I use PCBWay a lot because of the quality and fast delivery. This time, I ordered an FPGA board and a slightly more complex electronic paper control board.

I use PCBWay a lot because of the quality and fast delivery. This time, I ordered an FPGA board and a slightly more complex electronic paper control board.

MAX10 FPGA board

Overview

I wanted to experiment with the MAX10 FPGA 10M02, so I made an evaluation board.

To take full advantage of the MAX10 FPGA, all of the MAX10 FPGA's IO pins are pulled out to the pin headers. Generally, the evaluation board has various components such as a sensor on it, but in my case, I don't need those components and I want to use it in its original state as much as possible, so I have only connected a 50MHz clock to it.

There is also a regulator IC for FPGAs, and the FPGA can be operated by inputting 5 V from USB or dedicated pins. The power supply contains a 350mA polyswitch so that if something goes wrong during the experiment and it shorts out, the power is still turned off.

There are also LEDs connected to the four IOs, so you can check the operation of the program. The resistor connected to the LED is 10kΩ, so there is almost no effect on the input and output.

Schematic

Other than the power supply and the FPGA, there is only a bypass and a connector.

Artwork in KiCad

It was difficult to place and wire because there is a lot of wiring and bypass capacitors. The 144-pin package is pretty big. Turning it 45 degrees makes it easier to wire.

There are 1 mm holes in the four corners of the PCB. This is the hole for aligning the stencil with the PCB when printing solder using the stencil. You can align by inserting thumbtacks. It's a very easy and accurate method of positioning.

The main PCB and the discarded board are connected to each other with perforations. It used to be a V-cut, but I found that PCBWay added an extra charge for V-cutting, so I changed it to perforation. For the perforation, I used a drill diameter of 0.3 mm and a pitch of 0.635 mm.

Electronic paper control PCB

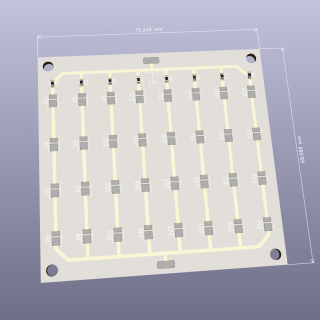

ESP32 and MAX V CPLDs are mounted on this electronic paper control PCB.

Protocol conversion with MAX V CPLDs allows the ESP32 to control the electronic paper and send drawing data via SPI communication. Since drawing data can be sent via 20 MHz SPI communication, screen updates to e-paper can be made quickly.

Artwork

Wiring on KiCad. The wiring is very detailed, can the PCBWay produce it well?

As with the FPGA, there are 1mm holes in the four corners of the PCB to align with the stencil. Also, the main PCB is connected to the discarded board with perforations. In the space between the main board and the discarded board, the word "APERTURE" is written on silk to make it easier for the PCBWay operator to identify it as an opening during production.

Order to PCBWay

The gerber data created on KiCad should be zipped together.

Go to PCBWay's website and click on "Get a quote now".

Set up the PCB to be ordered

Set the size of the PCB and the number of pieces, and then just specify the color of the PCB and the color of the silk to your liking, and then the setting of the PCB is complete.

Set up stencils to order

I don't have a stencil printer, so I always use frameless metal masks.

The important part is to set the "existing reference point" to "where the laser will pass through" in order to drill a hole in the PCB for alignment with the stencil.

Also, the original size of the stencil is 19cm x 29cm, which is too large for a 10cm x 10cm PCB, so I wrote "Cut to 15cm x 15cm" in the "Other Special Processing" section. Japanese is also fine.

These are the stencil settings that I always do. Click on "Calculate" to view the estimate.

Uploading data and waiting for review

After "Add to Cart", you will be prompted to upload the Gerber data. Upload the KiCad Gerber data compressed into a zip.

Once you upload your data and click "Order Now", PCBWay will begin reviewing your data to ensure it is correct. It took me about 5 to 15 minutes to get approved and be able to pay.

Now you just need to order and you're done.

What a surprise, production was completed the next day!

The board I ordered this time was completed the day after I ordered it. Now all I have to do is wait for the package to arrive. I like this kind of quick work by PCBWAY.

It was an introduction to how to order PCB from PCBWay.